CNC ROUTERS FOR HOBBY, BUSINESS,

INDUSTRY AND EDUCATION

German-Engineered, assembled and supported in the USA

Discover the Power of STEPCRAFT Desktop CNC Routers

Unlock endless possibilities with STEPCRAFT CNC machines, designed to handle aluminum, wood, plastic, and so much more. Our precision-engineered, computer-controlled milling machines deliver unmatched accuracy and reliability, empowering you to bring your ideas to life.

Whether you’re a hobbyist, maker, or model enthusiast; a professional in CNC production, prototyping, or small-batch manufacturing; or an educator introducing CNC technology in the classroom, STEPCRAFT has the perfect machine for your needs.

German Precision. USA Support. Unmatched Quality.

At STEPCRAFT, we combine world-renowned German engineering with the convenience of local USA support. Our CNC milling machines and components are meticulously crafted at our global headquarters in Menden, Germany, ensuring the highest standards of precision and reliability.

To bring you even closer to excellence, our Ready-To-Run systems and Q-Series machines are fully assembled at our USA headquarters in Torrington, Connecticut. From here, we proudly handle all sales and support for North and South America, providing you with responsive, expert assistance every step of the way.

With STEPCRAFT, you get the best of both worlds: cutting-edge German design paired with the dependable support you need to succeed. Experience the difference today!

From Hobby Projects to High-Volume Production STEPCRAFT Has You Covered

With three distinct CNC machine series available in eight different sizes, STEPCRAFT offers the perfect solution for every application—whether you’re crafting intricate models or scaling up to high-volume production.

Our machines run on the intuitive UCCNC drive system software, and we’ve got you covered with a comprehensive, free online course to help you master it with ease.

Curious about CNC technology and milling? Dive into our resources! Learn the basics of CNC and discover what makes milling such a versatile tool on our “What is CNC?” and “Milling” pages. Need guidance on CAD and CAM programs? Check out our “CAD CAM Programs at a Glance” guide for expert insights.

At STEPCRAFT, we’re here to empower you with knowledge, precision, and the tools to bring your vision to life.

STEPCRAFT D.SERIES

For model making, makers, schools, small businesses

- 3 different sizes

- Working area up to 23.4″ x 32.8 x 5.2″

- Available as a kit or Ready-to-Run System

- Multifunctional CNC milling machine thanks to CNC accessories

STEPCRAFT M.SERIES

For workshops, schools and production facilities

- 4 different sizes

- Working area up to 38.5″ x 56.8″ x 7.6″

- Available as a kit or Ready-to-Run system

- 2 machine table levels and Freestyle Milling™

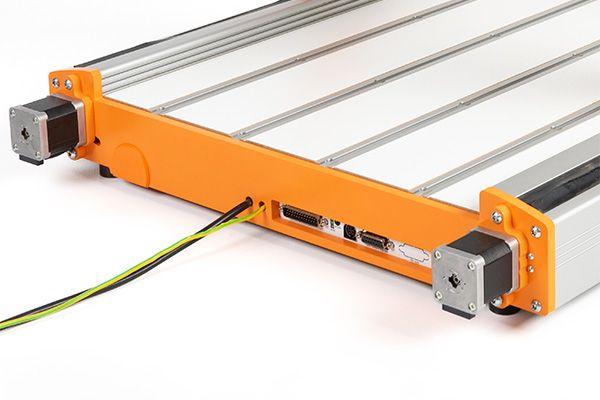

STEPCRAFT M.1400 Ultimate

For small to medium-sized production shops

- Work area of 38.5″ x 56.8″

- Fully encapsulated wiring

- Precision Ball Screws Drive System

- Job Positioning System (JPS)

STEPCRAFT Q-SERIES

For small to medium-sized production shops

- Working area up to 4 x 8 foot

- 7HP Automatic Tool Changer

- Vacuum Table for superior material hold-down

- Job Positioning System (JPS) for pinpoint accuracy

We make it possible for everyone to turn their ideas into reality with a CNC. Our team is dedicated to your success and we are here for you before, during and after the sale!

Start Your Own Business With A Stepcraft All-In-One Creation System

It has never been easier to take an idea that you have and turn it into a product or a business. Stepcraft's All-In-One Creation CNC Systems have been the centerpiece of many businesses and have helped bring countless products to life.

CNC Systems

Three machine series, eleven sizes, limitless application possibilities! The CNC portal milling machines can be expanded as desired with our CNC accessories.

CNC TOOLS

Convert the STEPCRAFT D-Series and M-Series in no time! Whether HF spindle, rotary axis or laser: with us you will find the right tool for every project.

CNC BOOKS

The quick introduction to CAD, CAM and CNC technology! We will show you the entire journey from the idea to the finished workpiece. With lots of tips and tricks.

SERVICE

Quickly looked it up! Our detailed construction and operating instructions provide you with optimal support in setting up, using and maintaining your products.